Deep-Sea Mining and ROV Technologies: Enabling Evidence-Driven Seabed Operations

Deep-sea mining (DSM) is moving from theory toward controlled experimentation, driven by growing demand for critical minerals such as nickel, cobalt, manganese, and copper. EyeROV's ROV technologies are enabling more efficient and cost-effective exploration, enabling the development of new materials and processes for deep-sea mining.

Deep-sea mining (DSM) is moving from theory toward controlled experimentation, driven by growing demand for critical minerals such as nickel, cobalt, manganese, and copper. According to the International Seabed Authority (ISA), 22 contractors currently hold 15-year exploration contracts across international seabed regions, covering more than one million square kilometers of ocean floor.

These contracts are strictly exploratory. Commercial extraction has not yet been approved, largely due to unresolved environmental and regulatory questions.

At the same time, scrutiny is intensifying. In 2021, the International Union for Conservation of Nature (IUCN) adopted Resolution 122, calling for a moratorium on deep-sea mining until biodiversity risks are better understood and managed. As a result, DSM is developing under a level of environmental accountability rarely imposed on extractive industries at such an early stage.

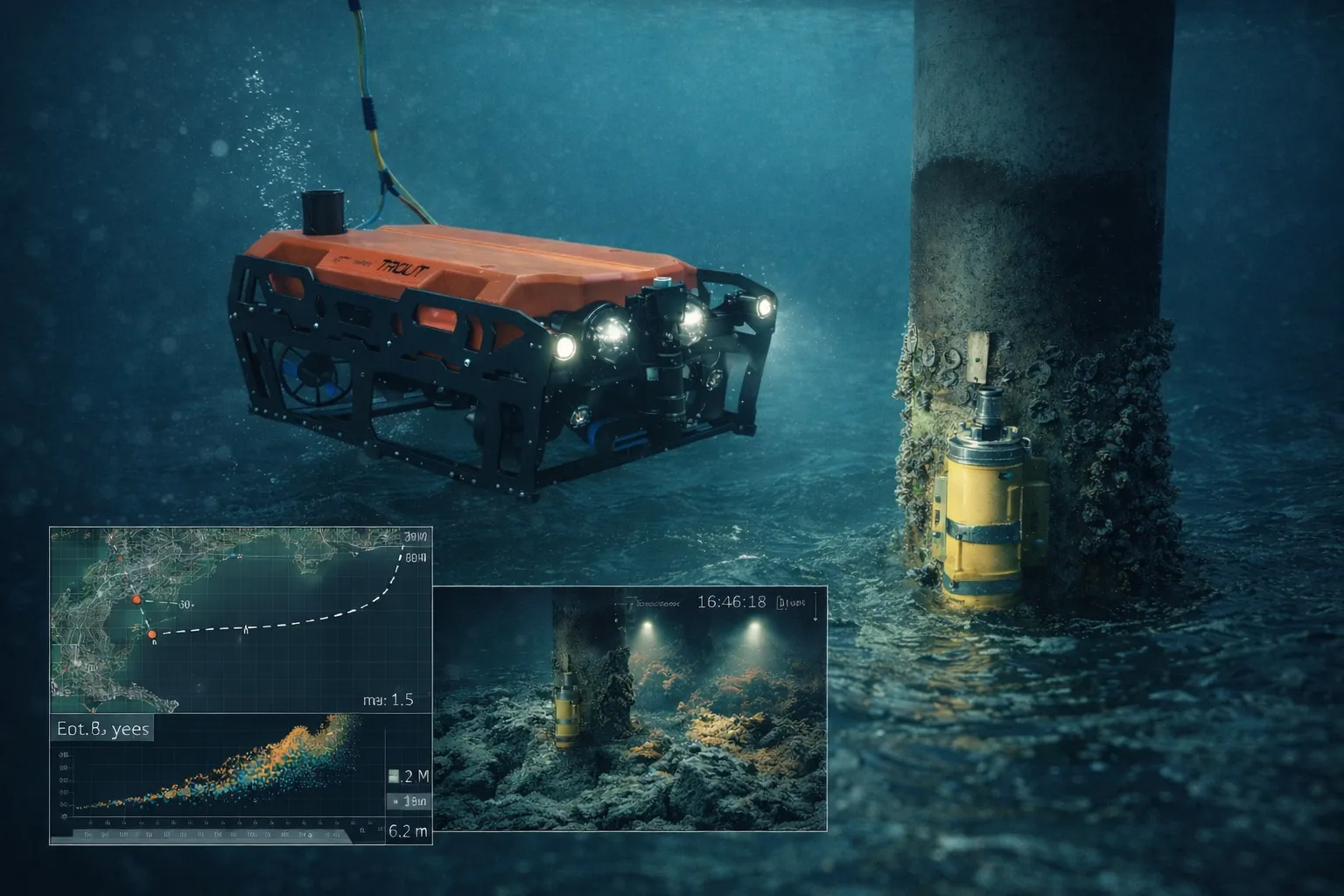

In this environment, success will depend less on extraction capacity and more on the ability to generate continuous, verifiable underwater evidence. This is where remotely operated vehicle (ROV) technology becomes foundational.

Why ROVs Are Fundamental to Deep-Sea Mining

A typical DSM program unfolds across three operational phases, each defined by distinct data requirements.

Prospecting and Site Characterization

Target seabed environments often lie between 3,500 and 6,000 meters in depth and feature highly heterogeneous terrain and localized biological communities. Accurate site characterization requires:

Repeatable visual transects

Bathymetric and seabed morphology surveys

Ground-truthing of acoustic and remote sensing data

Ship-based sensors alone cannot deliver the sub-meter visual resolution required. ROVs remain the only practical tool for direct, high-confidence seabed observation.

Environmental Baseline and Monitoring

Environmental baselines must be established years before any extraction activity begins. These datasets form the reference point for measuring change during and after operations, including:

Benthic habitat structure

Sediment disturbance extent

Water column turbidity

Faunal presence and distribution

Without ROV-based inspection, these parameters cannot be observed directly or revisited with sufficient consistency.

Operational Inspection and Integrity Management

DSM introduces complex subsea systems, collectors, lift systems, cables, deployment frames, and monitoring instruments, operating under extreme pressure, zero natural light, and limited access windows. ROVs are the only scalable method for routine inspection, fault detection, and documentation under these conditions.

Environmental Impacts That Persist for Decades

Scientific observations from a mining simulation conducted in 1979 in the Clarion-Clipperton Zone demonstrate the longevity of seabed disturbance. More than 40 years later:

Sediment tracks remain clearly visible

Large benthic fauna densities remain significantly reduced

Sediment compaction and geochemical changes persist

These findings suggest that DSM impacts are effectively permanent on human timescales. Consequently, regulators increasingly require quantitative proof of minimized impact rather than qualitative assurances.

Sediment Plumes: The Most Measurable Risk

Among all environmental risks, sediment plumes are the most directly measurable and modelled. Plumes can spread horizontally for kilometers, potentially affecting ecosystems far beyond the mined area.

Experimental studies have shown that plume behavior is strongly influenced by operational parameters such as nozzle height and flow velocity. Under controlled adjustments, reductions in suspended sediment concentration of up to 70% have been observed.

The implication is clear: plume behavior is controllable, but only if it is measured in real time. This creates a hard operational requirement for ROV systems capable of synchronizing video, navigation, and environmental sensor data to link equipment behavior directly to plume response.

Inspection-Led ROV Systems in Practice

As DSM operational footprints increasingly resemble offshore energy systems rather than conventional mining sites, inspection-led ROV frameworks developed for ports, subsea infrastructure, and offshore assets are becoming directly applicable.

These approaches emphasize:

Repeatable survey geometry

Consistent camera and lighting configurations

Time-linked visual and sensor data

Structured, auditable datasets

While abyssal mining occurs at extreme depths, a substantial portion of DSM operational time is spent outside the final mining zone, during nearshore trials, deployment testing, infrastructure inspection, and environmental monitoring. These phases account for the majority of survey hours and are critical for evidence generation.

Evidence-First Reporting and Regulatory Confidence

Future DSM approval frameworks are expected to require:

Baseline datasets with defined spatial and temporal resolution

Monitoring data explicitly linked to operational timestamps

Reports traceable to raw visual and sensor evidence

Inspection-plus-analytics models help transform underwater activity into structured, reviewable datasets. This approach supports regulatory evaluation, scientific analysis, and risk assessment by insurers and financiers.

What DSM-Ready Operations Look Like

A data-driven DSM monitoring framework typically includes:

Quantified baseline surveys

Repeatable transects with consistent camera geometry, lighting, and metadata.

Real-time plume observation

Synchronized visual and sensor data supporting immediate operational adjustment.

Continuous integrity inspection

Routine inspection of subsea infrastructure across ports, nearshore zones, and offshore interfaces.

Author Perspective: EyeROV

EyeROV works across ports, offshore infrastructure, and high-scrutiny underwater environments where decisions must be supported by verifiable data. From our experience, the most critical shift in subsea operations is moving from visual confirmation to structured evidence, where every inspection is repeatable, time-linked, and defensible. As industries like deep-sea mining evolve under increasing regulatory oversight, this evidence-first mindset is becoming essential rather than optional.

Bottom Line

Deep-sea mining is shaping up to be one of the most data-intensive extractive industries ever proposed. Environmental impacts may persist for decades, while sediment plume behavior can shift rapidly based on operational choices.

The organizations most likely to succeed will be those that can measure continuously, monitor quantitatively, and report transparently. ROV-enabled inspection and evidence generation sit at the center of this capability.

In a sector where permission to operate depends on proof rather than promises, data-driven underwater visibility will define the future of deep-sea mining.