Top 20 Uses of ROV for Underwater Inspection and Maintenance

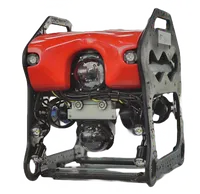

Discover the comprehensive applications of Remotely Operated Vehicles (ROVs) in underwater inspection and maintenance across marine infrastructure, offshore platforms, environmental monitoring, and subsea operations. From dam safety audits to pipeline integrity checks, explore how ROV technology revolutionizes underwater assessments while ensuring safety and efficiency.

1. Dam Upstream and Downstream Inspection

ROVs enable efficient dam safety inspection services, particularly in submerged or hard-to-access areas. They detect fractures, leaks, and erosion without dewatering, ensuring thorough upstream dam maintenance checks and monitoring wear in high-flow zones. Providing real-time visual and sonar data, ROVs enhance dam structural safety audits, support preventive maintenance, and ensure dam safety and longevity.

2. Surge Shaft, Surge Tank, Trash Rack, and Penstock Pipe Inspection

ROVs enable safe, efficient surge shaft integrity checks and inspections of critical hydro plant components like penstocks, trash racks, and surge tanks. They detect corrosion, blockages, structural damage, and silt buildup in submerged or hard-to-reach areas, enhancing reliability through penstock pipe corrosion audits and trash rack structural assessments. Detailed visual and sensor-based data ensure safety and longevity of hydropower facilities.

3. Bridge Inspection

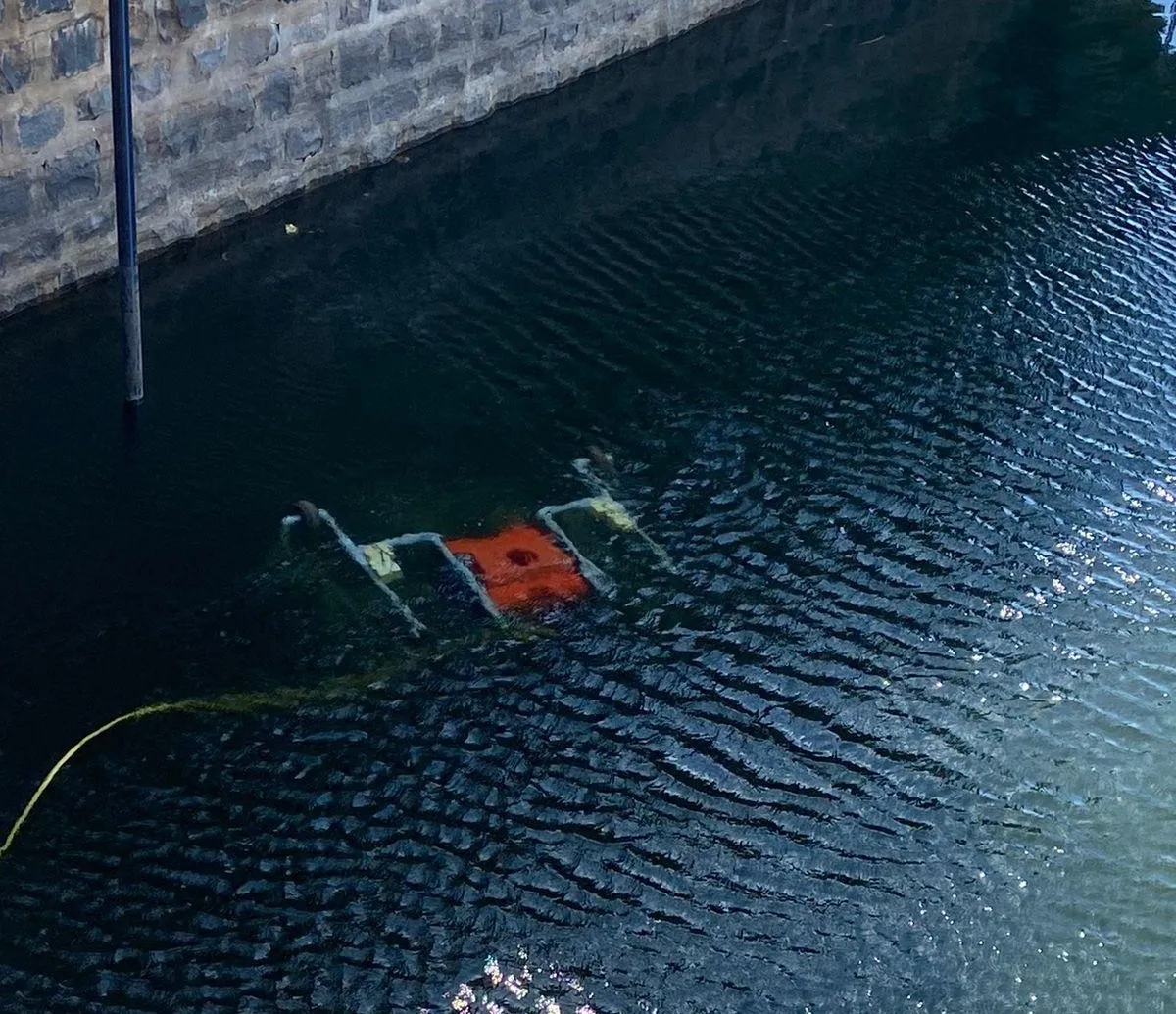

ROVs enable safe, efficient bridge structural safety audits, focusing on submerged bridge piers and abutments. They detect scouring, erosion, cracks, and material degradation, providing detailed visual and sensor-based bridge deck condition assessments without needing divers. This approach supports the bridge maintenance inspection checklist, ensuring structural integrity, safety, and longevity of bridge infrastructure in challenging underwater environments.

4. Tunnel Inspection

ROVs efficiently perform tunnel safety inspection services for hydro tunnels like headrace, tailrace, and diversion tunnels, offering real-time, non-invasive monitoring of structure, sediment, joints, and blockages. With high-resolution visuals, sonar, and geotagged data, they ensure tunnel structural integrity audits and reliability without dewatering or manual entry, supporting long-term tunnel lining inspection protocols and performance.

5. Jetty Inspection

ROVs offer a safe, efficient alternative to diver-based jetty structural safety audits, critical for ports, harbors, and marine operations. They enable thorough coastal jetty condition assessments in hazardous underwater environments, ensuring jetty maintenance inspection services maintain structural integrity, operational safety, and regulatory compliance while reducing risk and inspection costs.

6. Pipeline Inspection

ROVs enable efficient pipeline integrity testing services for underwater pipelines, including internal sections, risers, diffusers, and free spans. They detect corrosion, cracks, and sediment buildup in confined spaces, providing high-resolution gas pipeline safety audit data without shutdowns or diver entry, ensuring operational reliability while minimizing safety and environmental risks.

7. Water Tank Inspection

ROVs offer a safe, efficient solution for water tank safety audits, inspecting tank bottoms and shells with visual checks, spot cleaning, and UT thickness testing services without human entry. They reduce downtime, enhance safety, and provide high-quality data, making them ideal for water storage tank inspections and structural integrity assessments in confined environments.

8. Reef Inspection

ROVs enable non-intrusive, high-resolution coral reef health assessments, vital for monitoring rocky reefs that support diverse marine life across various depths and climates. These reefs sustain complex ecosystems, and ROVs facilitate marine reef inspection dives, aiding conservation and research efforts without disturbing the environment.

9. Biodiversity and Habitat Monitoring

ROVs are vital for biodiversity monitoring field services, capturing detailed visuals and geolocated data in hard-to-reach marine ecosystems using HD cameras and sensors. With tools like side scan sonar, they enable environmental habitat monitoring services and non-intrusive seabed mapping, supporting marine research and conservation without disturbing sensitive underwater habitats.

10. Offshore Platform Inspection

ROVs play a key role in offshore platform safety audits, providing safe, efficient access to underwater areas. Using HD cameras, sonar, and NDT tools, they detect corrosion, cracks, and marine growth, ensuring offshore structural integrity checks and regulatory compliance while reducing downtime without risking diver safety.

11. SPM PLEM Inspection

ROVs provide safe, efficient SPM PLEM integrity checks for Single Point Moorings (SPMs) and Pipeline End Manifolds (PLEMs), key offshore transfer points for oil and gas. They deliver high-resolution visuals and sensor data to detect wear and damage, enhancing mooring system safety inspections, regulatory compliance, and maintenance while reducing reliance on divers.

12. X-mas Tree, Risers, and Umbilical Inspection

ROVs facilitate safe, real-time X-mas tree integrity audits and inspections of subsea risers and umbilicals—key components in offshore oil and gas flow control. Utilizing advanced sensors and imaging systems, they detect corrosion, ensuring riser system safety inspections and compliance with industry regulations. By eliminating divers, ROVs prevent failures and support uninterrupted offshore production.

13. FPSO Inspection

ROVs play a critical role in FPSO safety inspection services for subsea systems, including moorings, risers, and turrets, particularly in deepwater or hazardous environments. Equipped with advanced imaging sonar, they enable floating platform condition audits, detecting corrosion, fatigue, and structural anomalies, ensuring safety, regulatory compliance, and optimized maintenance to extend FPSO operational life.

14. Subsea Pipeline Inspection

Remotely Operated Vehicles (ROVs) are crucial for subsea pipeline integrity checks, identifying corrosion, cracks, and free spans using high-resolution cameras, sonar, and advanced sensors. Capable of operating in deep environments without interrupting production, ROVs deliver accurate geolocation data, ensuring offshore pipeline safety inspections and long-term reliability of pipeline systems.

15. Vessel Inspection

ROVs provide a safe, efficient way to conduct vessel safety inspection services, inspecting hulls, propellers, and rudders while afloat, reducing dry-docking needs. Using high-resolution cameras and sensors, they detect corrosion, damage, and marine growth in real time, supporting marine vessel condition audits and ensuring structural integrity and navigational safety.

16. Geosynthetic Tube Inspection

ROVs offer a safe, efficient solution for geosynthetic tube integrity checks used in shoreline protection. Outfitted with cameras and sonar, they detect tears, displacement, and deformation, while evaluating sediment accumulation. This non-intrusive approach ensures coastal geosynthetic tube inspections maintain structural integrity, performance, and durability without divers.

17. Breakwater Inspection

ROVs provide a safe, efficient method for breakwater structural safety audits, identifying armor unit displacement, scouring, cracks, and marine growth. Equipped with high-definition cameras, sonar, and positioning systems, they capture precise underwater data for coastal breakwater condition checks, enhancing structural stability assessments and supporting timely maintenance of coastal defense structures.

18. Shipwreck Survey

ROVs enable safe, non-intrusive shipwreck underwater survey services for archaeology, environmental studies, and investigations. Equipped with HD cameras, sonar, and navigation systems, they provide detailed underwater shipwreck exploration audits, preserving site integrity while delivering high-quality data for analysis and supporting the protection of underwater cultural heritage.

19. Search & Recovery Operations

ROVs play a critical role in underwater search operation techniques, effectively locating wreckage, lost items, or missing persons in challenging, low-visibility conditions. Outfitted with imaging sonar, cameras, and manipulators, they deliver real-time visuals and data for marine recovery mission audits, enhancing operational decision-making, reducing risks to divers, and increasing mission efficiency.

20. UT Inspections

ROVs with ultrasonic thickness gauging (UTG) enable safe, efficient ultrasonic testing inspection services for water tanks and vessel hulls without drainage or dry-docking. Equipped with cameras, UT probes, and brushes, they clean surfaces, capture visuals, and measure wall thickness for non-destructive UT inspections, detecting corrosion or thinning and supporting accurate maintenance planning.